INJECTION MOULDING - FIRST-CLASS PLASTIC PARTS

Decades of know-how and passion

Professional injection moulding is our core competence and great passion

From simple series components to complex, individual high-tech precision parts - we manufacture almost every conceivable plastic injection moulding part for you.

Our core competencies at a glance.

Injection moulding

- Production of high-precision, technical plastic parts

- Excellent consulting competence with regard to customer-specific solutions

- High flexibility due to short distances and uncomplicated coordination processes

- Reliability - confirmed by supplier evaluations

- Adherence to delivery dates and deadlines

- Excellent product and economic quality

- Wide range of parts and applications

- Processing of almost all thermoplastics

- Tool designs are created in house

- Everything from one source

We are strong in this

Injection moulding - part variety, quality and professionalism

- Large series to small series

- Components with an injection weight of approx. 1g up to 2kg

- Simple geometries up to highly technical, complex components

- Carefully selected materials, from various filled materials, biocompounds to high-temperature materials

- Various materials, degrees of hardness or colours also used in multi-component injection moulding

We bring your idea into shape!

Advanced production

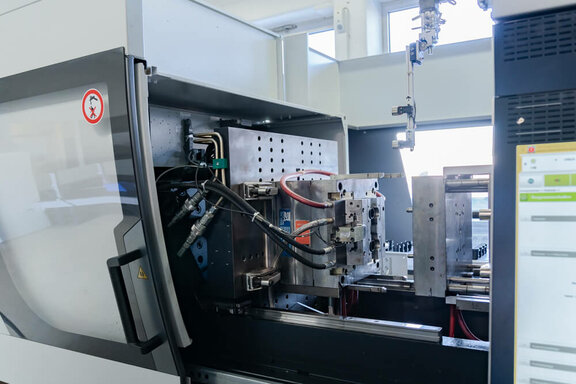

Machinery at the highest technical level

Our production currently consists of approx. 40 injection moulding machines, divided into three production halls. These include a clean room production facility in which we can manufacture parts and assemblies that are sensitive to cleanliness. The clamping force of our injection moulding machines ranges from 30 to 650 tonnes.

optimally equipped

Professional tools for high-quality results

There are currently about 1,000 active moulds in use, which have a size of up to approx. 1,500 mm x 1,450 mm.

After the production of the injection moulded parts, they are individually packaged according to customer requirements.

We offer an excellent range of technologies

Plastic injection moulding

- Compact injection moulding

- Metal overmoulding and fully automated insertion of metal parts

- Multi-component injection moulding (2K injection moulding)

- Thermoplastic foam moulding (TSG) for thick-walled geometries

- Gas injection moulding (GID)

- Highly automated production processes

- Assembly and finishing

this is what you should know.

Injection moulding

Economical production of plastic parts

Plastic injection moulding is a particularly economical manufacturing process for plastic parts. Even though the initial costs for the injection mould may seem high at first, the investment pays off.

Millions of plastic moulded partscan be produced with just onemould- and without any loss of quality.

The high precision and short manufacturing cycles predestine the process for economical series production.

proven

Plastic injection moulding is a proven process for producing plastic parts in high volume

Due to its cost-effectiveness and almost unlimited possibilities in terms of shape, design and structure of the plastic parts, injection moulding is a particularly popular method for the mass production of plastic parts.

high quality & diverse

High-quality plastic parts - Comprehensive manufacturing techniques and parts diversity

We offer effective solutions for almost every requirement. Our wide range of high-quality injection moulding techniques allows the problem-free implementation of the most diverse shapes and surface structures.

Whether uniform surfaces, different wall thicknesses, different materials and colour effects, we can produce even complex geometries for you in almost any size.

You can find out more under Injection moulding techniques and parts variety.

decades of experience

Plastics processing at the highest level

Over 55 years of experience, state-of-the-art technology and highly qualified employees are our foundation for excellent results and performance in plastics processing.

Numerous references and satisfied customers from a wide range of industries underpin our expertise, flexibility and reliability.